FEA Simulation

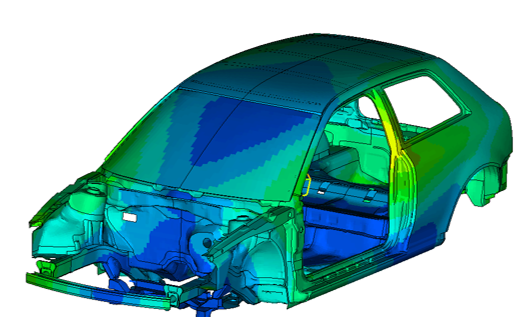

A system or component may be subjected to various loading conditions, requiring different types of validations such as static, dynamic, Acoustics, non-linear, impact, fatigue, thermo-mechanical, and fluid-structure interaction analyses, among others.

Selecting the appropriate FEA (Finite Element Analysis) software and the right type of analysis provides valuable insights into system behaviour at an early stage of the design cycle, significantly reducing iteration time and development costs.

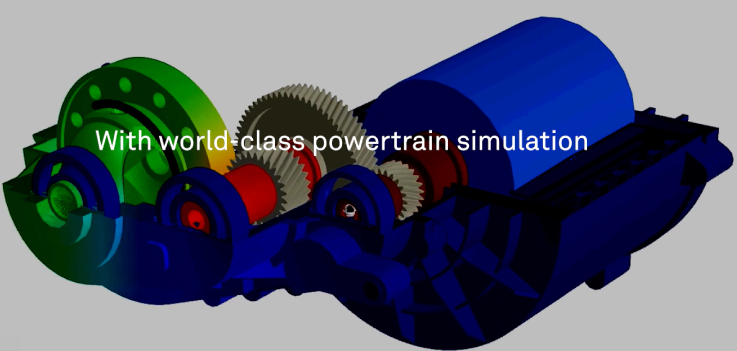

Systems Dynamics is the area enables understanding of interactions between various components within complex systems with a range of dynamic behaviours. simulation tools drive quality product design, through enhanced collaboration and reduced prototyping.

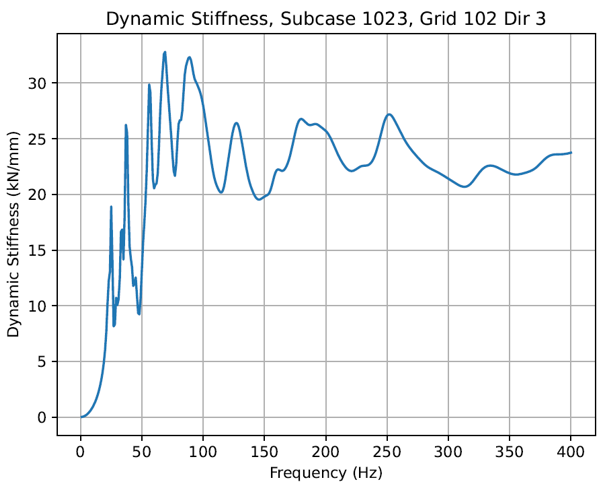

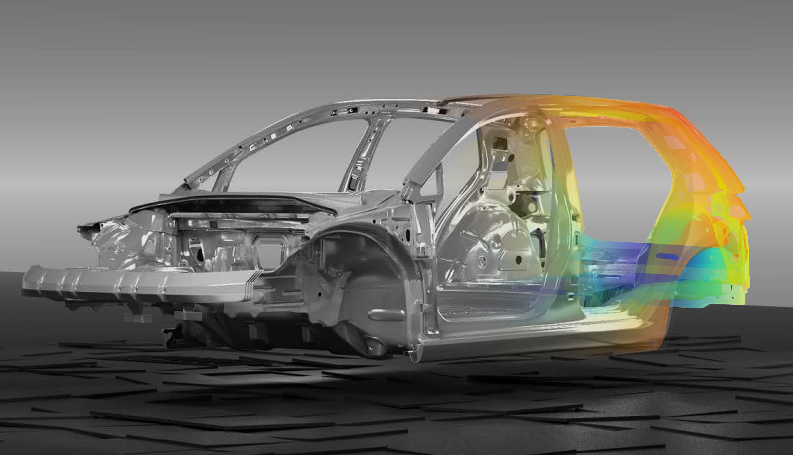

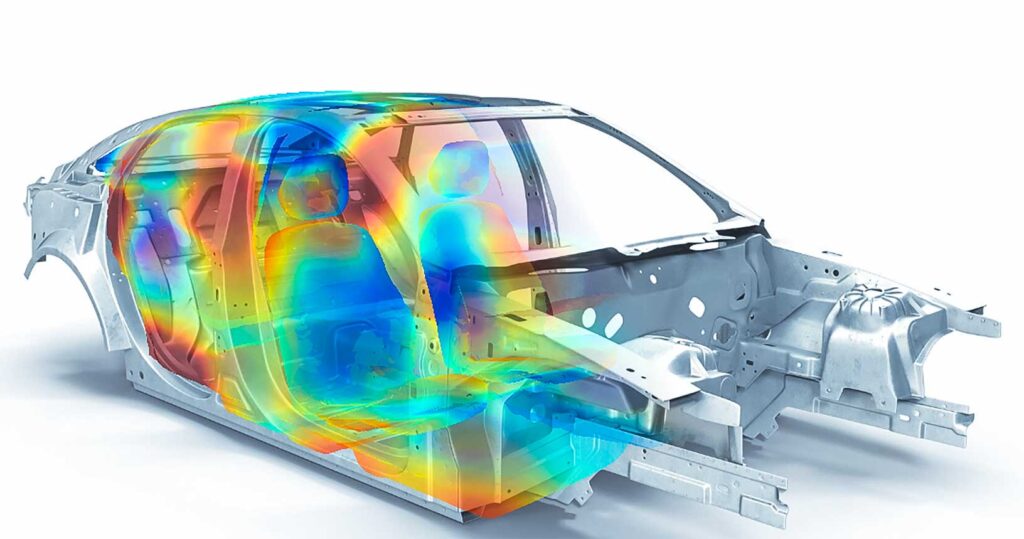

Dynamic Analysis

Dynamic simulations are essential in industries such as automotive, aerospace, civil engineering, and electronics, where understanding performance under motion or external excitation is critical.

Nonlinear Analysis

Nonlinear analysis is a powerful simulation method used to evaluate complex real-world behavior in materials and structures that go beyond simple, linear responses. It considers factors such as plastic deformation, large displacements, contact interactions, and material nonlinearity. This enables engineers to accurately predict performance under extreme loading conditions, validate product integrity, and reduce the need for physical prototypes.

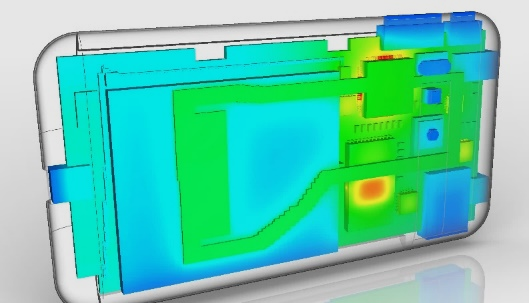

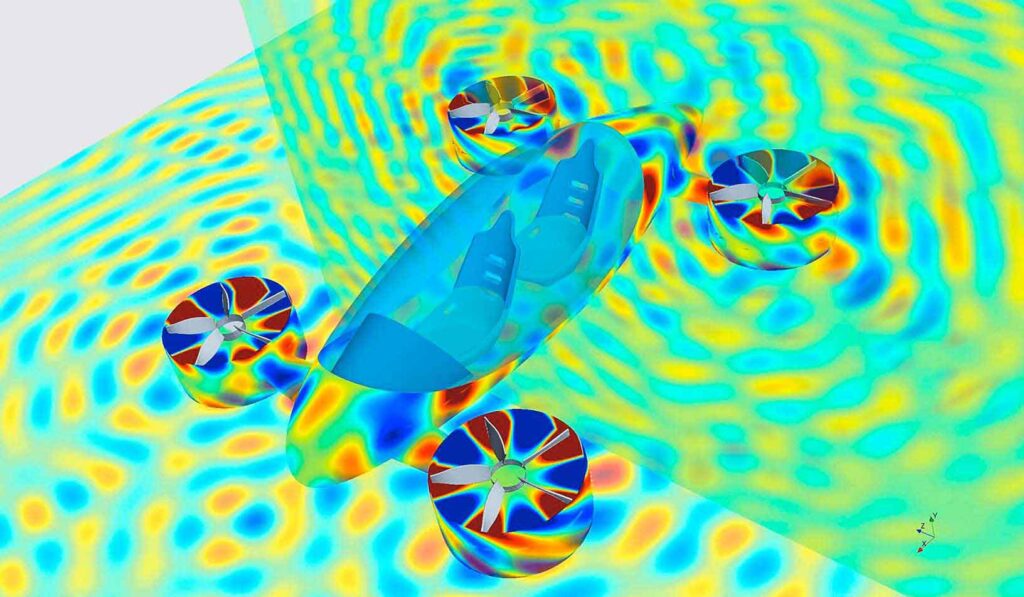

Acoustic Simulation

Acoustic simulation is a virtual testing method used to analyze how sound waves interact with physical environments, materials, and products. It helps predict noise generation, transmission, absorption, and vibration effects to optimize acoustic performance and reduce unwanted noise or resonance.

Engineers use acoustic simulation to design quieter products, improve sound quality, and ensure compliance with noise regulations—especially in automotive, aerospace, consumer electronics, and building acoustics.

Why FEA?

- Early Design Validation: Understand component response at an early design stage

- Reduce Iterations: Minimize redesign cycles through virtual testing

- Cost-Effective: Save time and money by reducing reliance on physical testing

- Risk Reduction: Identify potential failure zones in safety-critical designs

- Performance Optimization: Improve strength, durability, and material use

Benefits of FEA Simulation

- Accurate prediction of stress, strain, displacement, and temperature

- Capability to simulate linear and non-linear behavior

- Evaluate thermal and thermo-mechanical responses

- Validate impact and fatigue performance over life cycles

- Enhance product performance and reliability

- Supports both component-level and system-level simulations

Who Can Benefit

- Product Design Teams

- CAE Analysts

- Structural Engineers

- Thermal and Fluid Analysts

- Regulatory & Safety Engineers

How We Add Value

By integrating FEA into your product development cycle, Techvibes Systems Pvt Ltd helps reduce design risk, improve durability, and accelerate time to market. We work across industries including Automotive, Aerospace, Energy, Medical Devices, and Heavy Engineering.

Your Innovation Partner

Whether you're optimizing a production line or validating a new product design, we're here to help you move forward—faster, smarter, and with confidence.