AI Enabled Vision-Based Process Inspection

Smarter Process Control. Real-Time Insights. Zero Surprises.

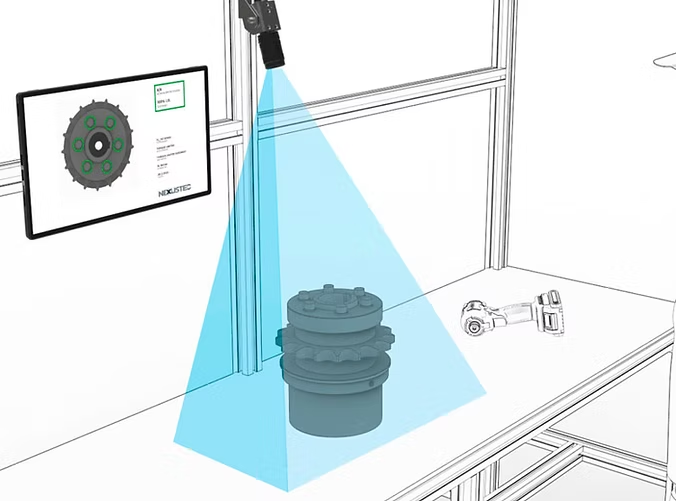

TVSPL’s AI-Enabled Vision-Based Process Inspection is a real-time, intelligent monitoring system that tracks and validates every step of the manufacturing process using cameras, sensors, and AI algorithms. It ensures process consistency, compliance, and optimization across your production line—both manual and automated.

The solution empowers manufacturers with data-driven process validation, inline anomaly detection, and operator guidance, all while generating comprehensive traceability data for continuous improvement.

Why You Need This

Many manufacturers face challenges like:

- Hidden process deviations that lead to downstream failures

- Lack of visibility into operator-driven tasks

- Manual documentation with no real-time quality triggers

- Increased rework due to unchecked process variation

TVSPL’s system solves this by providing real-time process visibility, automating inspections, and enabling process governance at every stage.

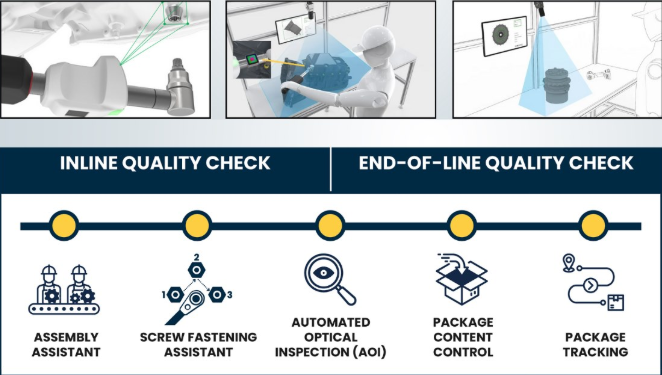

Core Capabilities

- Live Process Monitoring: Track real-time progress, detect missed steps or deviations

- AI-Powered Validation: Detect anomalies in motion, sequences, durations, or tool usage

- Guided Process Execution: On-screen visual cues to help operators perform tasks correctly

- Digital Traceability: Log process results, timestamps, tool data, and operator actions

- Offline Rework Tracking: Identify, document, and validate rework processes separately

- Flexible Integration: Works with existing tools, screens, cameras, or PLC systems

Benefits to Your Plant

- Zero Process Deviation: Ensure that every process step is executed correctly

- Reduced Human Error: Eliminate guesswork and manual reporting

- Increased First-Time Quality: Prevent faulty output at the source

- Audit-Ready Records: All process data is digitally captured and accessible

- Scalable Across Lines: Easily deploy on single stations or full production setups

- Operator-Friendly: Improves ergonomics and reduces training requirements

Built for Smart Manufacturing

This solution lays the foundation for:

- Advanced Process Control (APC)

- Smart Quality Management

- IIoT Integration & Data storage

- Automated Compliance Checks

- Closed-Loop Continuous Improvement

Industries We Serve

- Automotive Assembly

- Heavy Equipment Manufacturing

- White Goods & Appliances

- Defense & Aerospace

- Medical & Industrial Equipment

Your Innovation Partner

Whether you're optimizing a production line or validating a new product design, we're here to help you move forward—faster, smarter, and with confidence.