ETA-Dynaform

Sheet Metal forming simulation tool

DYNAFORM is a sheet metal forming simulation tool designed to improve all phases of the die development process to accomplish Die Design virtually. The system guides the engineer through cost estimation, quoting, die evaluation and formability simulation which can completely bypass soft tooling, reduce overall try-out time, lower costs and increase productivity for your organization

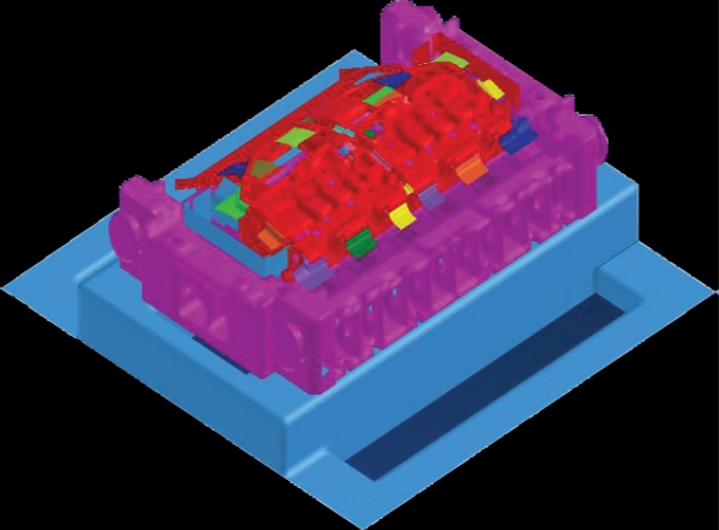

Analyze Die System Operations

Streamline modelling for scrap, trim dies, chutes & trim steel

Create trimming operations & shedding simulations

Simulate operational loads

Generate FEA models of the die structure Define operational & stamping loads

Evaluate die structure strength & durability Implicit & explicit solutions

Simulate metal transfer during manufacturing

Simulate transfer to die station, between stations & placement of finished piece on shipping rack

Predict interference between work-piece & tools

Use stress/strain results to prevent damage during transportation, & during loading & unloading operations

Blank Size Engineering

Costing engineers can simulate the formability and feasibility, improving development time and reducing change cost.

Dynaform determine material utilization and can optimize the use of material

Dynaform helps manufacturers reduce their sheet metal spend (light-weighting) and tooling costs

Dynaform decreases engineering changes due to formability issues by 33% on average.

Supports tailored blanks and double attached partsOptimal 1-up, 2-up , 2- pair, mirror and Multiple blank nesting

Separates Top and Bottom Surfaces of Solid Model Parts

Automatically generates middle Surface and does automatic meshing

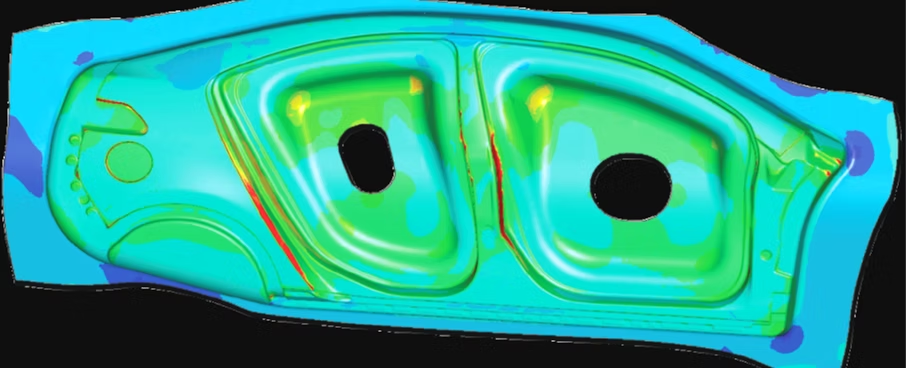

Uncover Design Flaws & Optimize Designs

Quick & easy set-up Multiple tools & multistation

progressive die simulations

User-friendly interface

Standard material types

Mild, high strength & stainless steel materials

New dual phase steel, aluminum & metallic alloys

Superplastic forming, Hot Forming, Hydroforming & Roller Hemming capabilities

Springback Analysis & Springback Compensation

Tube Bending for multi-stage rotary draw bending simulations