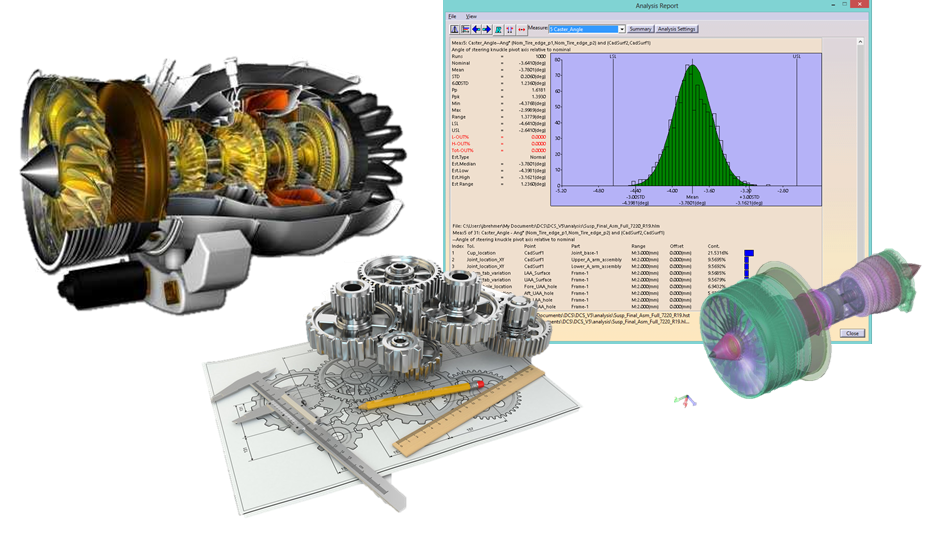

Dimensional Variation Analysis (DVA)

Dimensional Variation Analysis (DVA) is a simulation-driven process used to predict, analyze, and control dimensional and tolerance-related variation in assemblies—before physical prototypes are built. It creates a virtual build environment to understand how part tolerances, datum strategies, and assembly processes affect the final product’s quality and fit.

TVSPL delivers accurate and actionable insights by simulating variation scenarios across multiple sources, enabling smarter decisions during both design and manufacturing stages.

Why Use DVA?

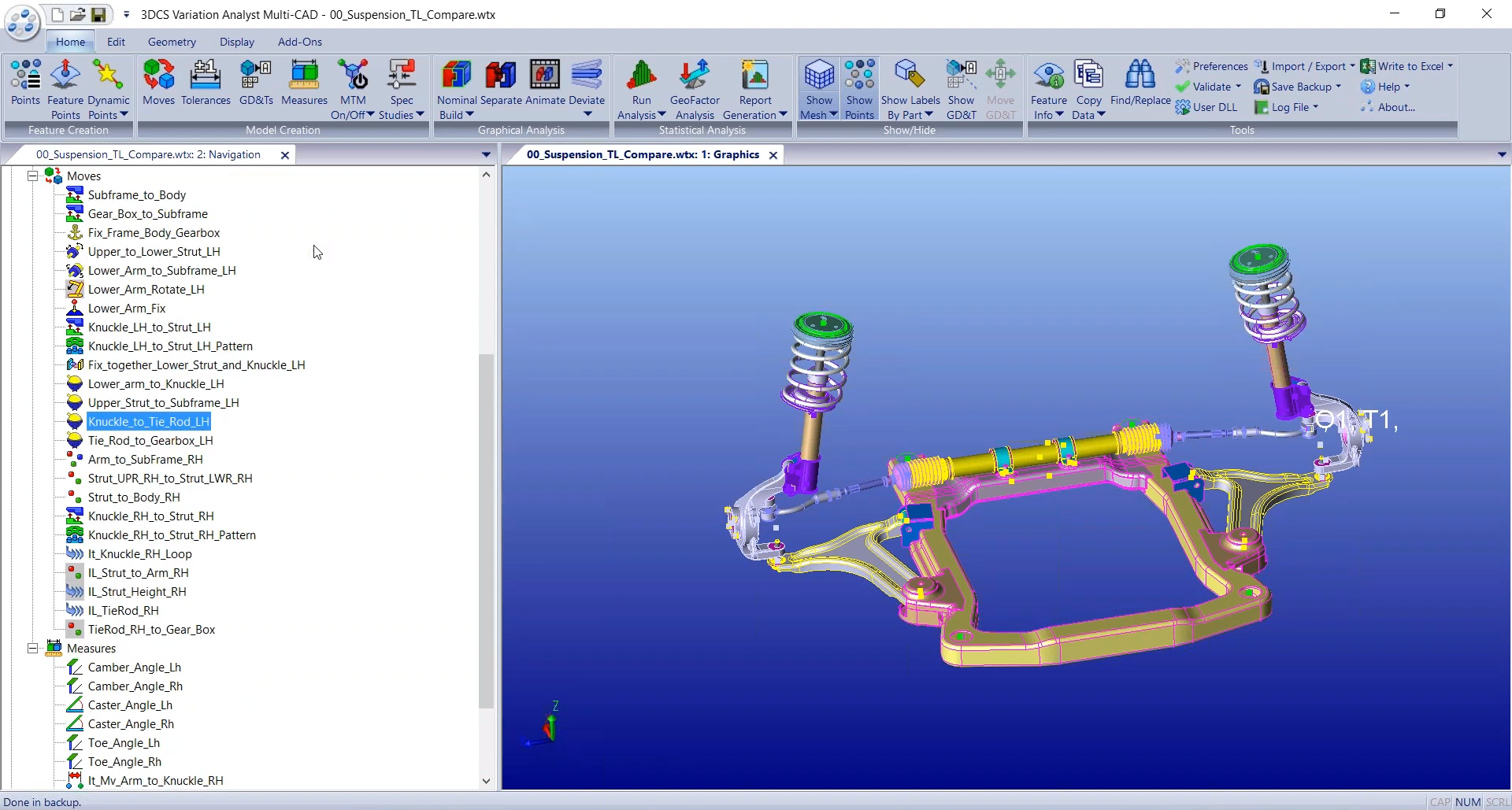

- Validate and Optimize GD&T: Test geometric dimensioning early in the design cycle and prioritize based on sensitivity and impact.

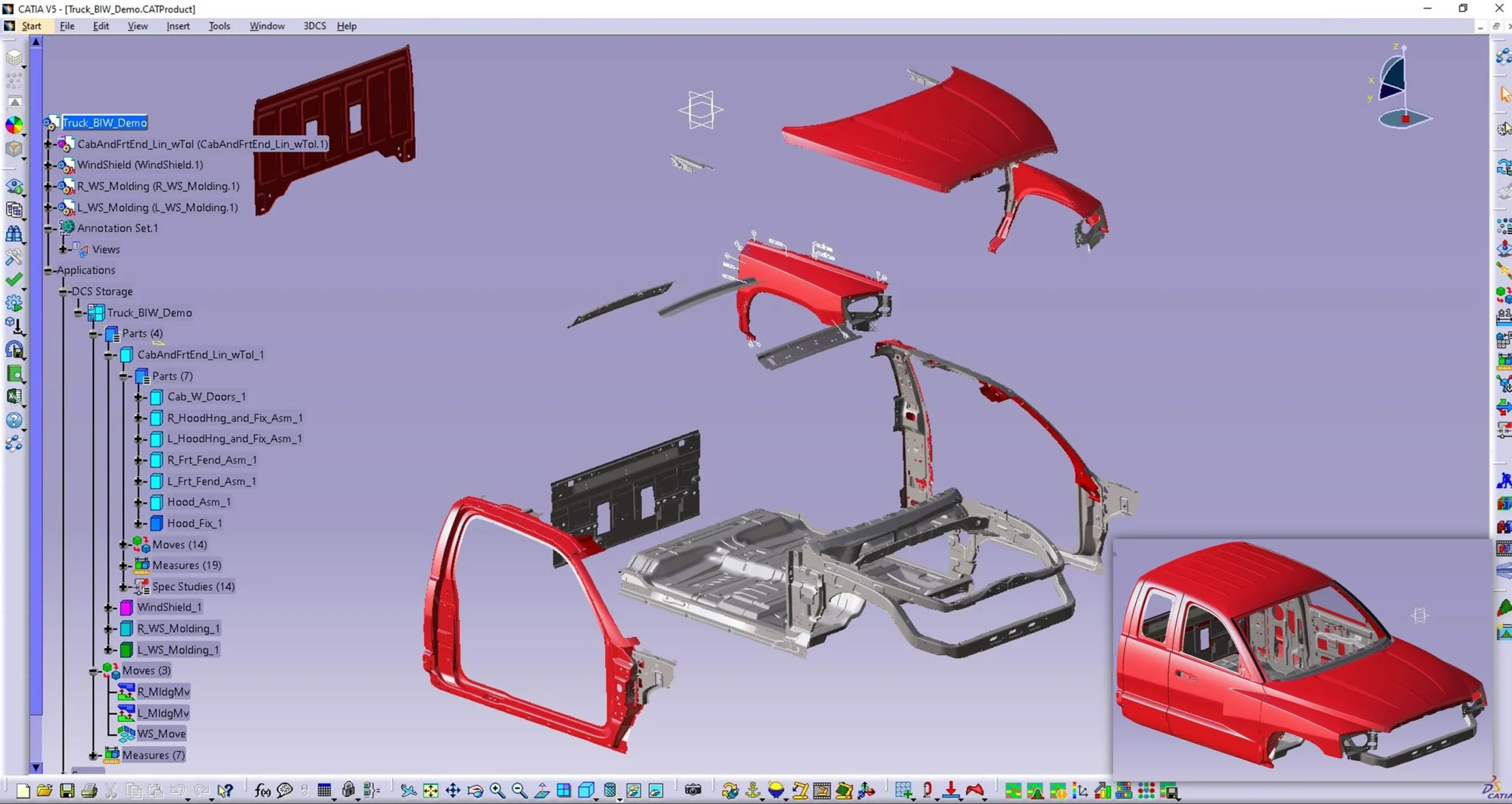

- Simulate and Improve Assembly Strategy: Evaluate different datum and locating schemes to ensure optimal process sequencing.

- Resolve Real Manufacturing Issues: Use plant measurement data to troubleshoot variation and avoid costly tool rejections.

- Predict Gap & Flush Conditions: Ensure fit and finish targets are met by adjusting fixtures and assembly methods virtually.

- Reduce Physical Prototypes: Build a digital twin of your assembly to validate build quality, saving cost and development time.

Benefits of DVA

- Insight into key contributors to variation

- Reduction in overall dimensional risk

- Improved fixture and tool design

- Better decision-making on design revisions

- Run what-if studies without manufacturing investment

Applications

- Automotive: BIW assemblies, interior/exterior trims

- Aerospace: Fuselage and wing assemblies

- Consumer Electronics: Tight tolerance stack-ups

- Medical Devices: Precision assemblies

- Heavy Machinery: Large structural fits

Who Can Benefit

- Product Design Engineers

- Manufacturing & Assembly Engineers

- Quality Assurance Teams

- Fixture & Tooling Designers

- Process Planners

Your Innovation Partner

Whether you're optimizing a production line or validating a new product design, we're here to help you move forward—faster, smarter, and with confidence.