Welding and Process Simulation

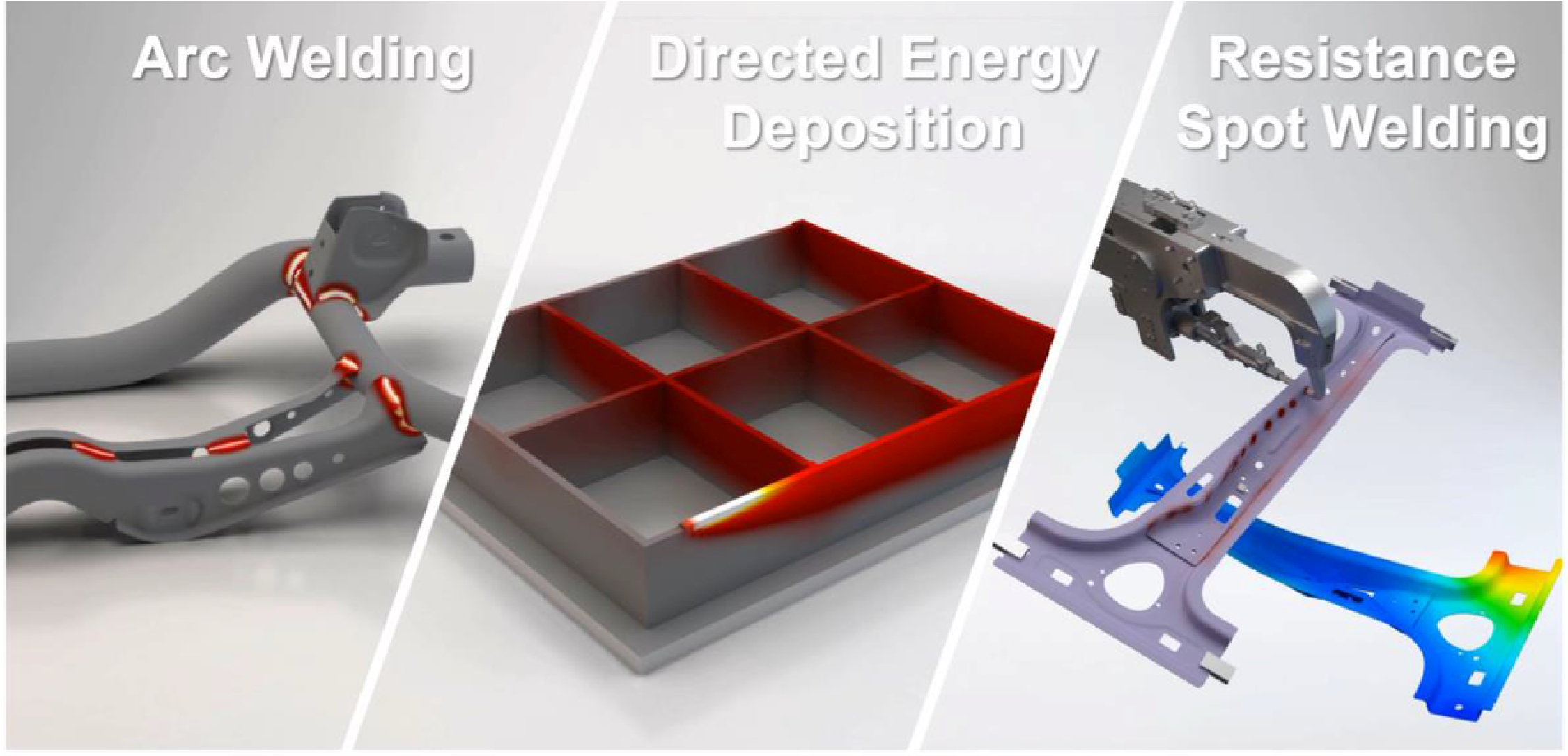

FE-Based Virtual Welding Simulation for Welding Assessment

To predict and assess potential adverse effects such as distortion and residual stresses in welded assemblies by simulating the welding process virtually before actual production.

Challenges Without Simulation

- Each assembly, material combination, and filler material vary, requiring unique parameters.

- Physical experimentation is often the only option without simulation, leading to:

- High iteration costs

- Limited ability to explore parameter space thoroughly

- Longer development cycles

How Simulation Helps Engineers

- Enables quick virtual trials by adjusting key parameters.

- Predicts distortion and residual stresses before welding.

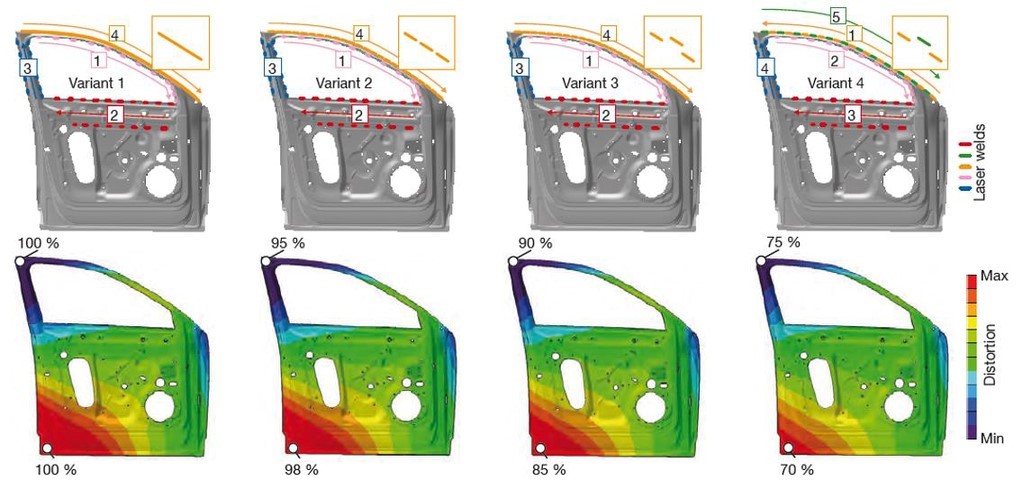

- Aids in selecting optimal clamping and weld sequences.

- Assesses need for preheating or cooling adjustments.

- Supports design improvement decisions with data.

Welding Parameters in Simulation

- Heat source characteristics: Intensity, distribution, and type (e.g., arc, laser).

- Weld velocity: Speed of the welding torch/application.

- Torch angle: Orientation relative to the weld joint.

- Weld sequence: Order in which welds are laid down, which affects heat buildup.

- Clamping: Location, duration, and stiffness of fixtures holding parts.

- Weld groove preparation: Geometry and fit-up conditions.

- Preheating and cooling: Thermal conditions before and after welding.

Key Benefits

- Cost and time savings: Physical trials are expensive and time-consuming. Simulations can reduce the number of physical iterations needed.

- Process optimization: Enables engineers to perform multiple what-if scenarios to fine-tune welding parameters.

- Design feedback: Provides insight on whether product design changes are necessary if distortion or residual stresses cannot be controlled.

- Improved quality: Helps in achieving optimal welding conditions leading to better assembly integrity and performance.